Engineering Validation, Load Testing & Certification

When your operation depends on lifting heavy, awkward, or safety-critical loads, confidence isn’t optional; it’s required. Plymouth Industries designs and fabricates certified below-the-hook lifting devices and forklift attachments backed by engineering analysis, physical validation, and professional certification when required.

From early design review to final documentation, we build lifting solutions that meet real-world demands, pass internal and external audits, and perform safely over the long term.

Engineered for Performance

Every certified lifting device begins with engineering rigor. We evaluate how loads move through the structure, where stress concentrations occur, and how the equipment behaves under operating conditions before fabrication ever begins.

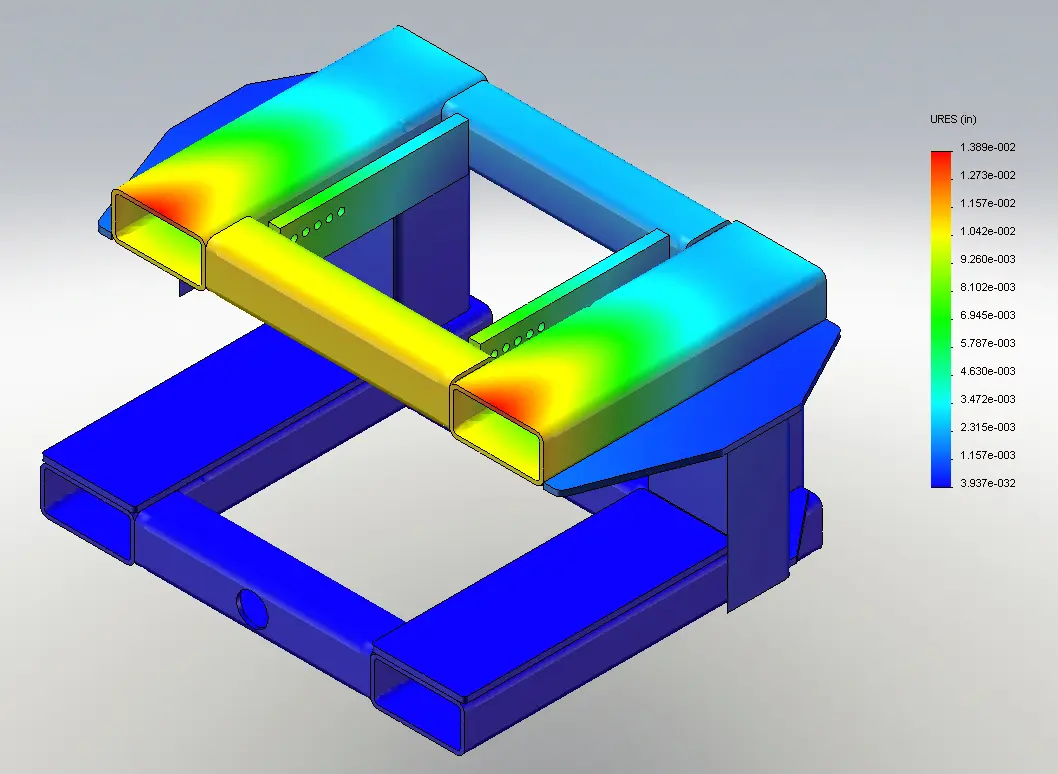

Finite Element Analysis (FEA)

We use advanced FEA modeling to analyze stress, deflection, and load paths during the design phase. This allows potential failure points to be identified and engineered out early, reducing risk, rework, and uncertainty.

What this means for your operation:

- Simulated real-world loading conditions before fabrication

- Verified structural integrity and safety margins

- Optimized material placement without unnecessary overbuilding

- Greater confidence in long-term durability and performance

Verified Through Physical Load Testing

For applications that require validation beyond theoretical analysis, below-the-hook lifting devices and lift truck attachments are physically load tested to confirm performance under rated and controlled overload conditions.

What this means for your operation:

- Confirmation of real-world behavior under load

- Validation of weldments, connections, and interfaces

- Support for internal safety reviews and audit requirements

- Reduced risk during commissioning and daily use

Load Rating & Professional Engineer (PE) Certification

In regulated or safety-critical environments, below-the-hook lifting devices and forklift attachments can be load-rated and certified by a licensed Professional Engineer (PE). Certification provides documented assurance that the equipment meets defined design assumptions and loading criteria.

Certification includes:

- Documented load capacity and design basis

- Certification aligned with customer, industry, or internal safety standards

- PE-stamped calculations and supporting analysis

Ideal for operations in:

- Aerospace and defense

- Automotive and heavy manufacturing

- Energy, infrastructure, and industrial processing

- Facilities with strict EHS or internal safety governance

Why Engineering Validation Matters

Certification isn’t about paperwork; it’s about protecting people, processes, and investments:

- Confidence for operators handling heavy or complex loads

- Confidence for safety teams approving equipment for use

- Confidence for leadership investing in long-term, compliant solutions

- Confidence during audits, internal or external

Well-engineered lifting devices reduce liability exposure, prevent costly downtime, and extend equipment life by ensuring the solution is right from day one.

Built Into the Project, Not Added Later

If your application requires engineering documentation, load testing, or PE certification, we scope it into the project from the beginning. That means no late-stage surprises, no retrofits, and no delays during approval or commissioning.

Our team works directly with your engineering, safety, and operations stakeholders to ensure every requirement is clearly defined and executed.

Let’s Engineer It Right the First Time

If your operation requires certified lifting devices, engineered forklift attachments, or documented load ratings, Plymouth Industries is ready to support your project. Contact us today to discuss your application, compliance requirements, and performance goals, and let’s build a lifting solution you can trust.