Plymouth Industries, Inc. is a leading material handling and industrial automation fabricator that specializes in returnable/reusable shipping and material handling carts and racks.

Our experience in utilizing a wide variety of dunnage materials sets Plymouth Industries, Inc. apart from the competition. Today’s manufacturing customers demand the most effective dunnage options to secure their products/parts during shipping and material handling. Listed below are our most frequently used dunnage processes and materials.

Plastics

UHMW | HDPE | Injection Molding | Custom Plastic Extrusion

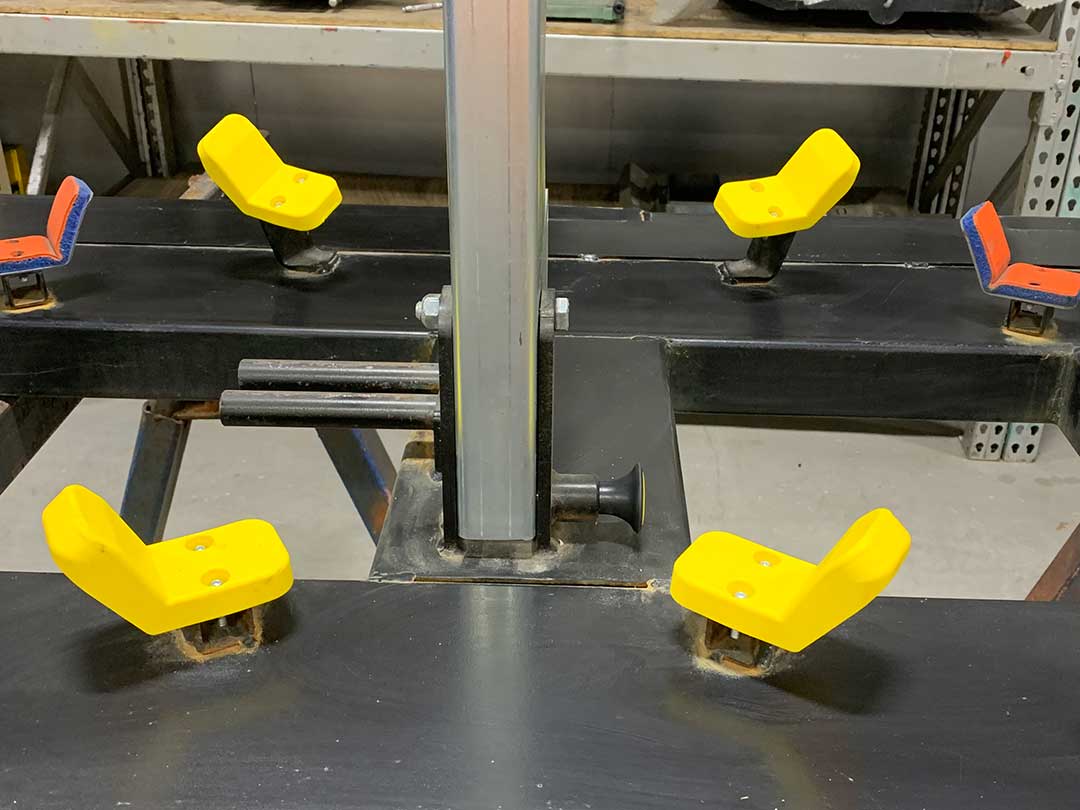

UHMW – Ultra-High Molecular Weight Polyethylene

UHMW is typically used in returnable/reusable shipping or material handling carts and racks when rigid high-density plastic dunnage is required. Its class A protective surface, moisture retardation, and hard durable material make it perfect for securing/transporting heavy products.

HDPE – High Density Polyethylene

HDPE is typically used in high-wear environments for returnable shipping racks or WIP (work in progress) carts that have impact resistance and durability dunnage requirements. The ability to machine HDPE allows for parts/products to be cradled creating secure shipping or material handling.

Injection Molding

Injection molding is best suited for high-volume runs in order to significantly reduce dunnage costs. Molded dunnage is custom manufactured to cradle products/parts reducing impact and vibration issues that occur during shipping or material handling processes. Typically it is used to provide maximum safety for high-value and/or fragile components.

Custom Plastic Extrusion

Custom plastic extrusion is most often utilized when channels for sliding drawers or parts/product storage is required as part of the dunnage package.

Foam

EPP | XLPE

EPP – Expanded Polypropylene

EPP is a malleable flexible closed-cell foam utilized in shipping and material handling environments with repeated impacts that do not require class A surface protection.

- Cost-Effective

- Rugged, Ideal for Heavy Products/Parts

- Multiple Impact Resistance

- Superior Cushioning Ability

XLPE/CLPE – Cross-Linked Polyethylene

The durability, long lifespan, and soft cushioning of XLPE make it the perfect fit for returnable shipping rack and reusable WIP (work in progress) cart applications.

- Class A Protective Surface

- Die, Saw, or Water Jet Cut for Precise Tolerances

- Superior Cushioning Ability

- Water Resistant

- Electrostatic Dissipative Option

Polyurea Coating

EX 450

Polyurea is a lightweight durable spray-on coating that creates a membrane on dunnage adding durability to cross-link foams and can be custom manufactured for a variety of uses.

- Waterproof

- Abrasion Resistant

- Hard or Soft Tensile Strength

- Class A Protective Surface

- Variable Thicknesses Optons

- Heat Resistant (FMVSS 302)

Urethane

Custom Molded Urethane

When securing and shipping parts or products that are sensitive to vibration, Urethane dunnage is the perfect solution for your shipping rack. It is well suited for dampening bumpers or bumper pad applications because it offers abrasion resistance and little or no rebound.

- Shock Absorption

- Vibration Dampening

- Abrasion Resistance

- Range of Hardnesses

Request a Quote

Plymouth Industries, Inc. stands behind our products and guarantees all workmanship. We only use high-grade materials and components, and believe a partnership with you will achieve more effective and efficient solutions. We look forward to the opportunity to work together soon.