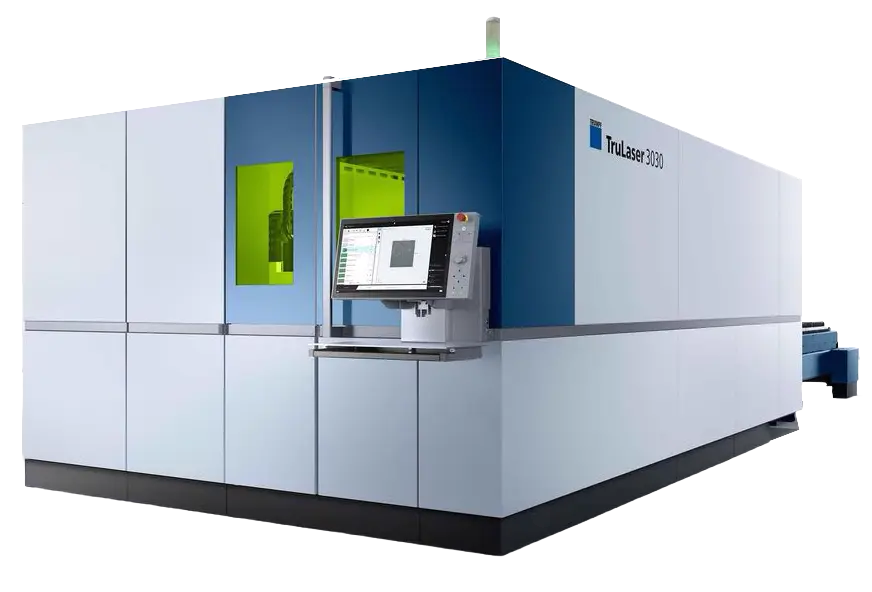

Maximizing Metal Fabrication with Trumpf 3030 Fiber Laser

Plymouth Industries has added laser cutting services to our in-house capabilities by purchasing a Trumpf 3030 Fiber Laser. We are excited to offer our customers faster turnaround times and greater part customization, and increased cost-effectiveness for all our material handling products.

Table of Contents

Introduction

The Trumpf 3030 Fiber Laser is a powerful tool for metal fabrication that want to improve their production processes and increase profitability. This machine has many advantages over traditional cutting methods, including higher precision and accuracy, increased production capacity, cost efficiency, and versatility.

Advantages of the Trumpf 3030 Fiber Laser

High Precision and Accuracy

Cut through different materials with high precision and accuracy, producing clean and smooth edges. Finished products and parts adhere to the highest quality standards.

Increased Production Capacity

High cutting speeds allow for increased production capacity compared to traditional cutting and laser cutting methods. This translates to faster turnaround times and a more efficient production processes.

Cost and Time Efficiency

CNC laser cutting with the Trumpf 3030 Fiber Laser reduces material waste and production costs, resulting in more time-efficient and cost-efficient operations. Its high cutting speed and precision reduce production time, lower labor, and minimize the need for post-processing, resulting in lower labor costs and increased profitability.

Materials and Versatility

Fiber Lasers cut through a variety of materials, including steel, aluminum, copper, and brass. It also has the ability to handle different thicknesses and sizes of materials, making it a versatile metal fabrication tool.

Design Capabilities

The Trumpf 3030 Fiber Laser allows for greater design flexibility, with the ability to cut intricate shapes and patterns.

Implementation of Custom Orders

The machine’s high cutting speed and precision handle enable low quantity custom orders to be cut efficiently and cost effectively.

Conclusion

The Trumpf 3030 Fiber Laser is a game-changer for metal fabrication, with its many advantages over traditional cutting methods. It allows for higher precision and accuracy, increased production capacity, cost efficiency, and versatility. Custom metal fabrication services and CNC laser cutting with greater ease and efficiency.