Efficient material movement is critical in industries managing large infrastructure components. To meet the demanding requirements of a leading utility provider, Plymouth Industries engineered a custom tilt-type cart designed for both strength and mobility in a heavy-use industrial environment.

WIP Carts

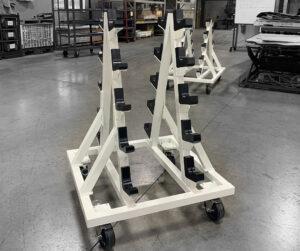

Innovative Work-In-Process Rack Designed for Aerospace Manufacturing

Plymouth Industries recently engineered and fabricated a custom Work-In-Process (WIP) Rack solution for a leading aerospace manufacturer known for its cutting-edge advancements in launch systems and high-precision component production. This rack was designed to meet the demanding requirements of aerospace component handling, ensuring efficiency, safety, and precision throughout complex assembly processes.

Custom Vertical Kanban WIP Cart for Streamlined Component Flow

In industrial environments, maintaining efficient workflow and minimizing downtime are top priorities. A global technology manufacturer recently partnered with Plymouth Industries to improve work-in-process (WIP) material handling on the production floor. The solution: a custom-designed Component Vertical Kanban Work-in-Process Cart, purpose-built to support organized and ergonomic inventory flow.

Injection Molding Storage Rack: Custom WIP Bag Rack

At Plymouth Industries, we recently engineered and fabricated a custom WIP rack to streamline work-in-progress storage for a leading marine composite manufacturer. This plastic parts storage rack serves as an industrial storage solution, specifically designed for injection molding operations, ensuring parts remain organized and protected throughout the production cycle.

5 Ways Work-In-Progress Carts Can Enhance Lean Manufacturing Practices

Have you ever watched a manufacturing floor operate like a well-oiled machine, with materials flowing seamlessly from one workstation to another? Behind this choreographed efficiency often lies an unsung hero: the work-in-progress cart. These mobile storage solutions have become indispensable tools for manufacturers looking to embrace lean principles and eliminate waste from their operations. At Plymouth Industries, we’ve seen firsthand how the right WIP cart can transform a chaotic production floor into a model of efficiency.

American Strength: Carts & Racks Made in the USA Matter

When it comes to streamlining your supply chain, improving operational efficiency, and reinforcing your company’s commitment to quality, your material handling solutions matter more than you think. That’s why choosing “Made in the USA” carts and racks isn’t just a patriotic gesture—it’s a smart business decision. From returnable shipping racks to WIP carts, domestic manufacturing provides unparalleled quality, customization, and consistency advantages. At Plymouth Industries, we believe in the power of American-made products to drive performance and strengthen your bottom line.

Top 10 Benefits of WIP Carts in Your Manufacturing Facility

In today’s fast-paced manufacturing world, optimizing production flow and increasing efficiency are crucial for staying competitive. That’s where work-in-progress carts—also known as WIP carts—come in. These specially designed carts are more than just tools for transporting goods; they’re essential equipment that help streamline operations, enhance safety, and support lean manufacturing goals.

Maximize Productivity: Every Manufacturer Needs WIP Carts

In today’s manufacturing environment, the need for speed and efficiency is paramount. A simple yet effective tool that streamlines production processes is the Work In Progress (WIP) cart. Let’s explore why every manufacturer should consider integrating WIP carts into their operations.