In the heart of every manufacturing facility, where sparks fly and metal meets metal, production welding stands as one of the most critical processes driving our modern industrial economy. Consumers see finished products like cars, bridges, skyscrapers, and appliances. However, they often overlook the complex welding work that makes these items possible. At Plymouth Industries, we understand that welding isn’t just about joining materials; it’s about creating the foundation upon which entire industries are built.

Manufacturing Capabilities

Elevating Tube Laser Cutting Capabilities with New Trumpf TruLaser Tube 5000 Fiber

This significant investment underscores Plymouth Industries’ commitment to expanding its advanced manufacturing capabilities and delivering superior-quality products to customers across diverse industries. The Trumpf TruLaser Tube 5000 fiber represents the pinnacle of tube laser cutting technology, enabling Plymouth Industries to process round, square, rectangular, and special profiles with unprecedented speed and precision. This advanced system handles tubes and profiles up to 6.5 inches in diameter and processes wall thickness up to 0.4 inches in mild steel.

From Blueprint to Perfection: Precision CNC Machining Services

Our CNC machine shop is dedicated to excellence and innovation. We provide complete solutions that meet the varied needs of our clients.

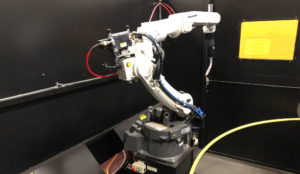

Robotic Welding: Transforming Manufacturing Excellence at Plymouth Industries

At Plymouth Industries, we’re committed to delivering cutting-edge manufacturing solutions that maximize quality, efficiency, and value for our customers. Today, we’re diving deep into one of our core technological advantages: robotic welding.

Hard Fixture Tooling in Welding: Why Plymouth Industries Chooses Precision

In the world of manufacturing, precision and consistency are key factors in producing high-quality welded components. At Plymouth Industries, we take pride in delivering durable, accurate, and repeatable welding solutions. One of the critical aspects of our process is the use of hard fixture tooling—a method that ensures superior results in every production run.

Maximizing Metal Fabrication with Trumpf 3030 Fiber Laser

Plymouth Industries has added laser cutting services to our in-house capabilities by purchasing a Trumpf 3030 Fiber Laser. We are excited to offer our customers faster turnaround times and greater part customization, and increased cost-effectiveness for all our material handling products.

CNC Brake Press – Dener Servo Advanced Bending Machine

As part of our planned growth strategy, Plymouth Industries, Inc has added the Dener Servo CNC Press Brake to our machine shop. This next-generation non-hydraulic advanced bending machine combines eco-friendly power consumption with faster productivity, increased accuracy, greater flexibility, and consistent reliability.

Robotics take Center Stage in 2020

With the recent purchase of a Miller PerformArc™ Robotic Welding Cell, Plymouth Industries, Inc. continues to create a metal manufacturing process that pushes the boundaries of quality and efficiency. Vice President Michael Knowles shares, “As our custom metal shipping rack, cart, and material handling equipment business grows, so does our need for automation.”

Addition of Marvel Spartan Iron Worker SIW60D

Heavy-duty construction and capability. Dual cylinder for multiple simultaneous dual operations. Punching capabilities up to ¾” thick. Shearing capabilities on square stock, flat bar, and angle stock.

Addition of a new Horizontal Scissor Style Metal Saw

Plymouth Industries, Inc. has added a new Horizontal Scissor Style Metal Saw to their facility. The addition of this device will allow for increased production capacity while also providing more accurate cutting of structural steel.