Efficient material handling is critical in high-volume manufacturing and distribution environments, especially within automotive supply chains where space utilization, durability, and part protection directly impact productivity. To address these challenges, Plymouth Industries designed and fabricated a custom collapsible stacking bin rack engineered for repetitive use, return logistics, and dense storage.

This project highlights how a purpose-built steel stacking bin rack can improve warehouse efficiency while reducing transportation and storage costs.

Designed for High-Volume Industrial Use

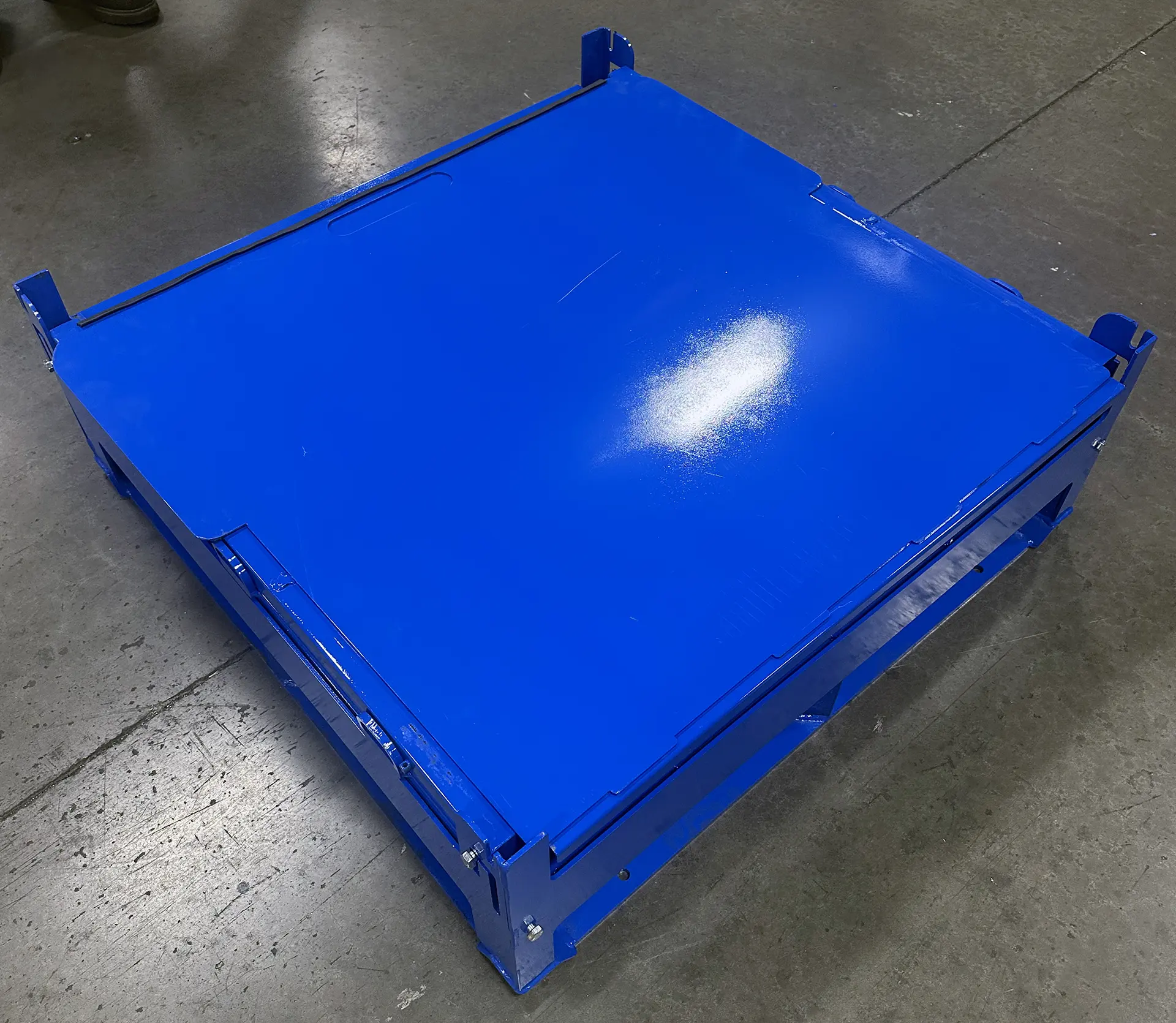

These stacking collapsible bin racks were engineered for a Tier 1 automotive components operation that requires consistent part flow between manufacturing, warehousing, and assembly facilities. The design supports heavy-duty use while maintaining flexibility for empty return shipments.

Each rack provides a compact yet robust solution for storing and transporting bulk components. When empty, the unit collapses to significantly reduce the cube, allowing more racks per truckload and lowering overall freight costs.

Key Features of the Collapsible Bin Rack Design

The rack incorporates several functional features that enhance safety, usability, and longevity in industrial environments:

- Collapsible end and side panels for reduced storage height when not in use

- Stackable steel frame with integrated stacking targets for secure vertical storage

- Removable HDPE center divider to separate parts and prevent contact damage

- Spring-loaded folding end gates with positive locking for ease of operation

- Forklift-accessible base designed for standard fork spacing

- Heavy-duty welded steel construction with industrial powder-coated finish

Design refinements included reinforced side gates, improved stacking interfaces, and optimized collapsed clearance to ensure consistent performance in demanding warehouse conditions.

Optimized for Space, Safety, and Part Protection

Unlike standard wire baskets or expendable containers, these collapsible steel bin racks are engineered to balance load capacity with part protection. The rigid steel structure prevents deformation under load, while smooth interior surfaces and optional dividers reduce the risk of scuffing or damage to finished components.

The collapsible design also supports lean manufacturing and returnable packaging strategies, helping reduce waste while maximizing warehouse density.

Applications for Collapsible Stacking Bin Racks

This style of industrial stacking bin rack is ideal for:

- Automotive parts manufacturing and assembly

- Tier 1 and Tier 2 supplier logistics

- Warehouse staging and work-in-process (WIP) storage

- Returnable packaging and closed-loop supply chains

- Heavy or high-value component transport

Because each rack is custom-engineered, dimensions, load ratings, gate styles, and divider configurations can be tailored to the application.

Built to Specification by Plymouth Industries

As with all Plymouth Industries projects, this collapsible stacking rack was designed, prototyped, and fabricated in-house to meet precise operational requirements. From structural integrity to ergonomic handling, every detail was refined to support long-term use in a high-throughput industrial environment.

Looking for a Custom Collapsible Bin Rack?

If your operation needs custom stacking bin racks, collapsible steel containers, or returnable material-handling solutions, Plymouth Industries can design and build a system that fits your workflow.

Contact our team today to discuss your application and request a custom quote.