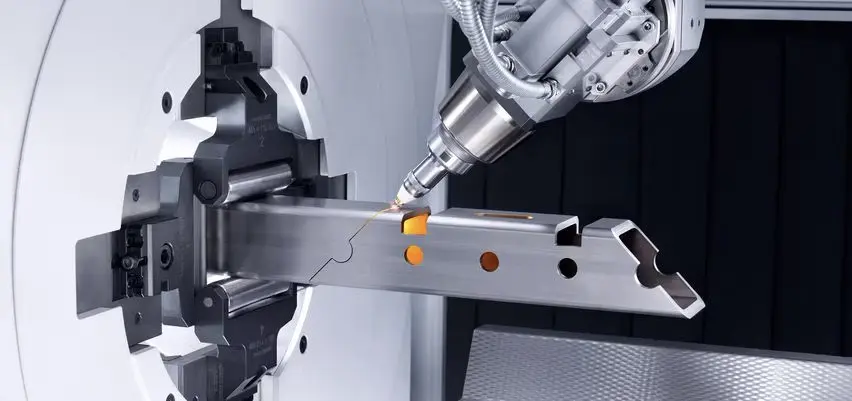

Plymouth Industries Elevates Tube Laser Cutting Capabilities with New Trumpf TruLaser Tube 5000 Fiber

State-of-the-art laser tube cutting technology enhances production capacity and precision for custom manufacturing solutions.

Plymouth, Wisconsin – May 28, 2025—Plymouth Industries (www.plyind.com), a leading provider of custom metal fabrication and manufacturing solutions, is pleased to announce the acquisition of the Trumpf TruLaser Tube 5000 fiber. This significant investment underscores Plymouth Industries’ commitment to expanding its advanced manufacturing capabilities and delivering superior-quality products to customers across diverse industries.

Advancing Tube Laser Cutting Technology

The Trumpf TruLaser Tube 5000 fiber represents the pinnacle of tube laser cutting technology, enabling Plymouth Industries to process round, square, rectangular, and special profiles with unprecedented speed and precision. This advanced system handles tubes and profiles up to 6.5 inches in diameter and processes wall thickness up to 0.4 inches in mild steel.

“This strategic acquisition of the TruLaser Tube 5000 fiber allows us to enhance our tube processing capabilities significantly,” said John J. Knowles, President at Plymouth Industries. “The system’s exceptional speed, flexibility, and precision enable us to deliver higher quality components with shorter lead times, ultimately providing greater value to our customers.”

The acquisition of the TruLaser Tube 5000 adds to our manufacturing core strengths and will positively impact all production areas, including Quality, Cost, and Delivery.

Enhanced Capabilities and Customer Benefits

The integration of this cutting-edge tube laser cutting system into Plymouth Industries’ production floor delivers several key advantages:

- Expanded Material Processing Range: Capable of cutting mild steel, stainless steel, aluminum, brass, copper, and various other metals with superior edge quality

- Increased Production Efficiency: Automated loading and unloading systems minimize setup times and enable seamless 24/7 operation

- Superior Component Quality: Precise cutting with minimal heat-affected zones ensures consistent, high-quality finished products

- Design Flexibility: Advanced software integration enables complex cuts, joints, and features that were previously unattainable with conventional methods

- Reduced Lead Times: Streamlined production workflow from design to finished parts accelerates project timelines

Commitment to Innovation

The Trumpf TruLaser Tube 5000 fiber investment reflects Plymouth Industries’ ongoing commitment to leveraging advanced manufacturing technologies. By continually upgrading capabilities and equipment, the company remains an industry leader in custom metal fabrication and precision manufacturing.

“At Plymouth Industries, we’re dedicated to staying at the forefront of manufacturing technology,” added John J. Knowles. “The addition of this advanced tube laser cutting system enables us to tackle increasingly complex projects while maintaining the highest standards of quality and efficiency our customers have come to expect.”

Staying successful means investing in technology that moves us forward. Our entire team is ecstatic about the flexibility that this laser provides.

The new system is now fully operational at Plymouth Industries’ manufacturing facility, expanding the company’s capacity to serve customers in automotive, aerospace, construction, energy, and more.