Plymouth Industries is your trusted partner in Wisconsin and beyond when searching for reliable, high-quality metal fabrication services. Our family-owned company has delivered exceptional custom fabrication solutions for over 40 years. If you need steel fabrication, aluminum work, or special rack services, we have the skills to make your ideas real.

Why Choose Plymouth Industries

Metal fabrication is more than just cutting and welding; it's the art and science of transforming raw metal materials into functional, durable products that meet your specifications. At Plymouth Industries, we understand that every project tells a story, and we're here to help you write yours with precision and excellence.

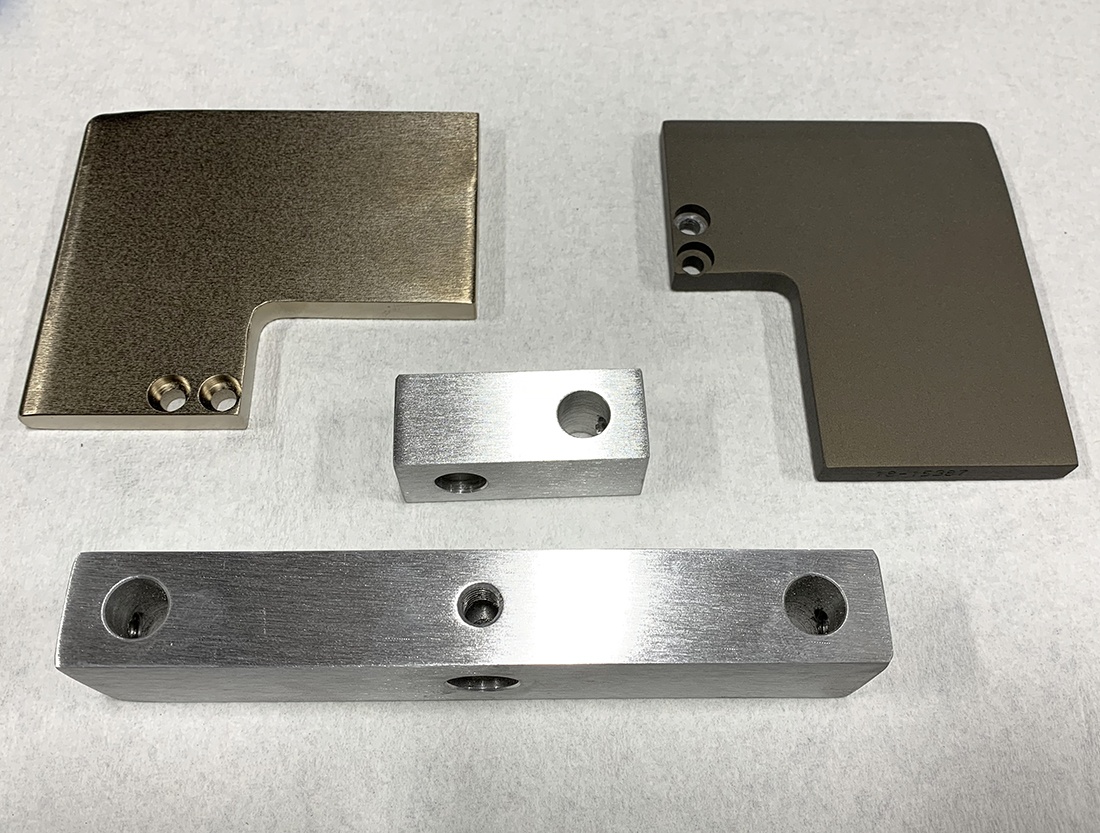

Our 75,000 square foot facility houses the latest fabrication technology, operated by skilled craftsmen who bring decades of experience to every project. From initial design and engineering to final assembly and finishing, we handle projects with attention to detail. Our metal fabrication capabilities include engineering, prototyping, sheet/tube laser cutting services, CNC machining, robotic welding, and quality control (CMMC). Whether you're in the automotive, aerospace, food processing, or industrial automation sector, we can exceed your expectations.

Steel Fabrication Services

Carbon Steel Fabrication Applications

Carbon steel fabrication offers exceptional strength-to-weight ratios, making it ideal for heavy-duty applications. Our carbon steel services include everything from simple brackets to complex structural assemblies. We work with various grades of carbon steel, selecting the perfect material for each application's specific requirements.

When you choose our carbon steel fabrication services, you're investing in durability that stands the test of time. We've fabricated everything from industrial automation equipment to custom shipping racks that travel thousands of miles, maintaining their integrity through countless loading and unloading cycles.

Industrial Steel Welding Services

Plymouth Industries' welding and fabrication shop department boasts TIG, MIG, and robotic welding services for steel, stainless steel, and aluminum metals. Our certified welders understand that a strong weld is the foundation of any reliable fabricated product. We follow industry standards and use high-grade welding materials. Whether your project requires precision TIG welding for thin materials or high-production MIG welding for structural components, we deliver consistent quality you can depend on.

Stainless Steel Fabrication Services

Stainless steel fabrication demands specialized knowledge and equipment, which we've invested heavily in. Our engineering staff and in-house design capability allow us to service stainless steel products from concept to fabrication. We work with our customers to improve their products or equipment through our design and manufacturing knowledge and experience.

Food-Grade Stainless Steel Applications

Stainless steel fabrication is critical in industries that require cleanliness and corrosion resistance. We understand the unique challenges of working with food-grade stainless steel, from maintaining proper surface finishes to ensuring all welds meet sanitary requirements.

Our stainless steel fabrication capabilities extend to pharmaceutical equipment, dairy processing systems, and commercial kitchen installations. We work with various stainless steel grades, including 304, 316, and specialty alloys, ensuring your finished product meets the most stringent industry standards.

Corrosion-Resistant Stainless Steel Solutions

Beyond food applications, stainless steel's corrosion resistance makes it invaluable in harsh environments. Whether you're dealing with chemical processing equipment or marine applications, our stainless steel fabrication services provide the longevity and performance your operations demand.

We've fabricated custom stainless steel components for everything from water treatment facilities to offshore equipment, where failure isn't an option. Our understanding of how different stainless steel alloys perform in various environments ensures you get the right material for your specific application.

Aluminum Fabrication Services

Aluminum fabrication offers unique advantages that make it perfect for applications where weight matters as much as strength. Custom aluminum fabrication for lightweight, durable solutions. Precision manufacturing for aerospace, automotive, construction, and industrial applications.

Lightweight Aluminum Manufacturing

Working with aluminum requires different skills and equipment from steel. Aluminum's thermal properties mean it conducts heat differently during welding, requiring precise control and specialized techniques. Our fabricators have mastered these nuances, delivering aluminum components that meet specifications.

The beauty of aluminum fabrication lies in its versatility. We can create everything from delicate electronic enclosures to robust structural components, all while maintaining aluminum's natural corrosion resistance and attractive finish.

Aerospace and Automotive Aluminum Fabrication

In the aerospace and automotive industries, every ounce matters. Our aluminum fabrication services help manufacturers reduce weight without sacrificing strength or safety. We understand the critical nature of these applications and maintain the quality control systems necessary to meet industry certifications.

Anodized coatings help to increase the life and usefulness of aluminum machines or parts by providing a stable PTFE (polytetrafluoroethylene) protective finish. Some key enhancements the right anodized coating provides include corrosion resistance, abrasion resistance, thermal resistance, dielectric resistance, lubricity, friction reduction, cleanability, and improved hardness.

Rack and Cart Repair Services

Sometimes, the most cost-effective solution isn't buying new; it's restoring what you already have. If your carts or racks are breaking in-house or during shipment, Plymouth Industries, Inc. will help you identify the improvements required to fix or improve them. Even if we did not initially manufacture the cart or rack, we will still repair, service, or refurbish it.

Steel Rack/Cart Repair and Refurbishing

Durable steel racks and carts can become damaged over time, leading to safety hazards and decreased efficiency. Our steel rack/cart repair process follows a systematic approach that minimizes downtime while maximizing safety. We start by identifying the root cause of the damage, then develop a repair strategy that addresses both the immediate issue and prevents future problems.

Rack/cart repair services extend the life of your material handling equipment while maintaining safety standards. We don't just fix the immediate problem; we engineer solutions that prevent future failures. This approach has saved our customers thousands of dollars in replacement costs while improving the overall reliability of their material handling systems.

Cart/Rack Modification

Your business evolves, and your equipment should evolve with it. Our cart/rack modification services transform existing equipment to meet new requirements, whether changing dimensions, adding features, or improving load capacity. We've modified everything from simple utility carts to complex automotive racks, always focusing on maintaining structural integrity while adding the necessary functionality. It's like giving your equipment a second life tailored to your current operations.

Rack/cart modification offers several advantages over replacement. It's typically more cost-effective, requires less downtime, and allows you to retain equipment already integrated into your operations. Plus, modifications can often improve functionality beyond what was originally designed. Rack/cart modification customizes an existing configuration to fit your specific needs.

Shipping Rack Fleet Refurbishment

Fleet refurbishment represents the ultimate in equipment lifecycle management. Rather than replacing entire fleets of shipping racks, refurbishment allows you to restore multiple units simultaneously, ensuring consistency across your entire operation.

Fleet Assessment and Diagnosis

Our fleet refurbishment process begins with a comprehensive assessment of your entire rack population. We identify patterns in wear and damage that might indicate systemic issues, then develop a refurbishment plan that addresses these root causes.

This systematic approach ensures that your refurbished fleet will outperform the original equipment, incorporating lessons from years of real-world use.

Refurbishment Cost-Effectiveness

The economics of fleet refurbishment are compelling. You can often refurbish an entire fleet for a fraction of the replacement cost, adding years of useful life and improving performance. It's an investment that pays dividends in reduced maintenance costs and improved operational efficiency.

Our refurbishment services have helped companies save hundreds of thousands of dollars while improving the reliability and safety of their material handling operations.

Why Plymouth Industries is Your Fabrication Partner of Choice

Choosing the right fabrication partner is about more than just finding someone who can cut and weld metal. It's about finding a team that understands your challenges, shares your commitment to quality, and has the expertise to deliver solutions that exceed your expectations.

Plymouth Industries is a leading manufacturer of custom returnable shipping racks, stack racks, warehouse carts, steel storage racks, and core (tube) carts. It is committed to producing high-quality products, providing value-added service, and creating a customer experience that separates it from the competition.

At Plymouth Industries, we don't just manufacture products, we build partnerships. Our commitment to quality, innovation, and customer service has made us the preferred fabrication partner for companies across diverse industries. From automotive manufacturers to food processors, our clients trust us to deliver solutions that drive their success.