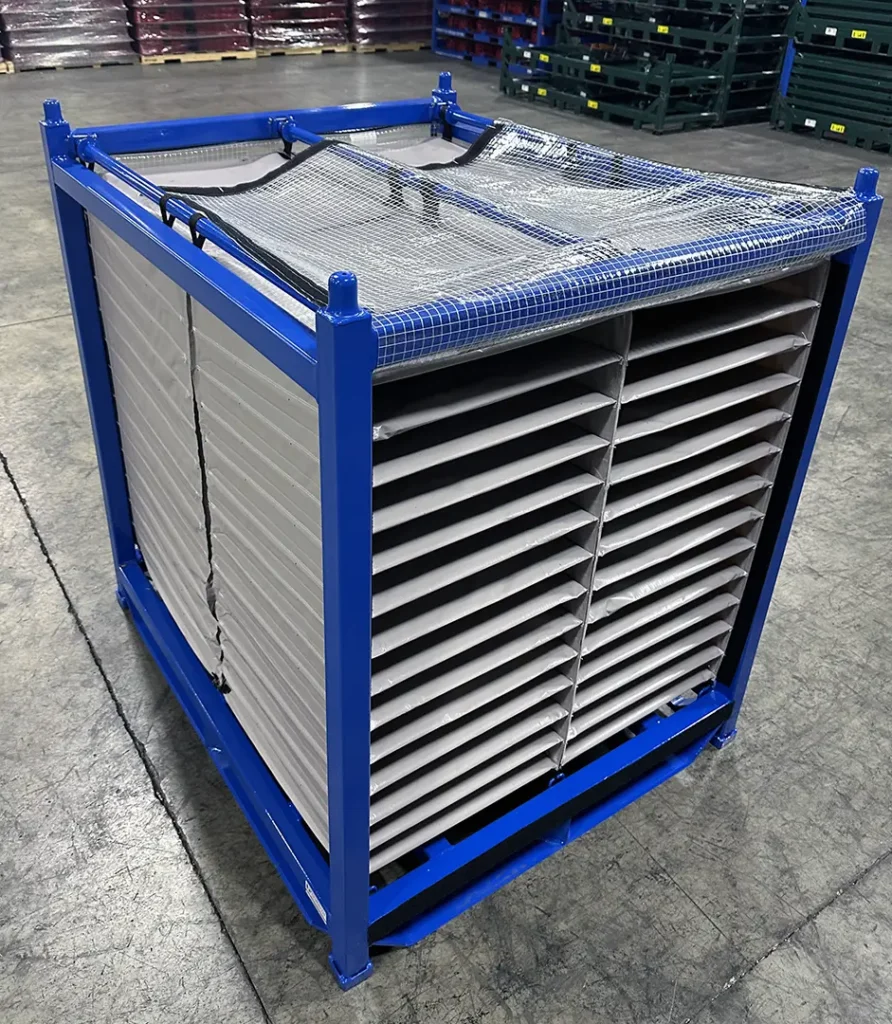

At Plymouth Industries, we recently engineered and fabricated a custom WIP rack to streamline work-in-progress storage for a leading marine composite manufacturer. This plastic parts storage rack serves as an industrial storage solution, specifically designed for injection molding operations, ensuring parts remain organized and protected throughout the production cycle.

Custom Design & Fabrication

Our plastic parts WIP rack features a heavy-duty steel frame with a corrosion-resistant powder-coat finish. Precision metal fabrication and skilled weldment create a robust steel WIP rack suited to high-volume manufacturing environments. From design concept through fabrication, this bag rack solution meets the exacting tolerances required for seamless material handling.

Key Features

- Bag Rack Inserts: Multiple reinforced fabric pockets accommodate individual trays of molded parts, offering clear separation and quick access.

- Secure Cover with Pocket: A durable mesh cover locks in parts and includes an integrated document pocket for work orders or traveler instructions.

- Forklift-Ready Base: Built-in pockets on the frame allow safe forklift entry and transport.

- Modular Work-in-Progress Rack: Scalable design lets you expand your storage footprint as production demands grow.

Front and side views highlight the rack’s modular layout and cover system, while the open-view images illustrate effortless part loading and unloading.

Conclusion

Ready to upgrade your material handling with a tailored work-in-progress rack or bag rack system? Contact Plymouth Industries today to discuss your custom WIP rack needs and request a quote. We’ll help you optimize storage, protect parts, and keep your injection molding workflow running smoothly.