Introduction

The need for speed and efficiency must be balanced in today’s manufacturing environment. Whether producing automotive parts or assembling electronics, every production process must run smoothly without unnecessary interruptions. A simple yet highly effective tool that helps streamline these processes is the Work In Progress (WIP) cart. Often underestimated, these carts play a pivotal role in enhancing workplace productivity, improving material handling, and reducing inefficiencies on the factory floor. So, let’s explore why every manufacturer should consider integrating WIP carts into their operations and how they can supercharge productivity.

What Are WIP Carts?

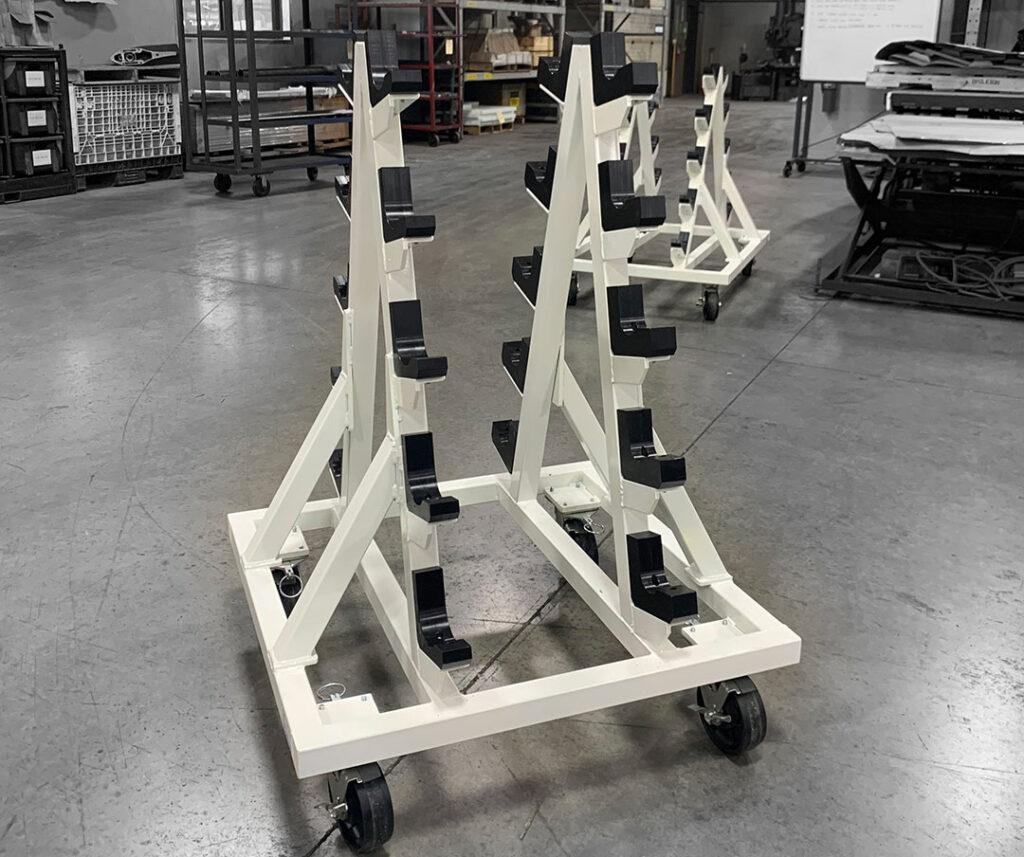

A Work-in-Progress cart, often referred to as a WIP cart or Work-in-Process cart, is designed to transport unfinished products and components between different stages of production. Unlike standard carts that may be used for general material handling, WIP carts are explicitly tailored to support active manufacturing processes. They come equipped with features such as shelves, dividers, and compartments that help organize materials at various stages of completion.

Types of WIP Carts

- Standard WIP Carts: Essential for moving products between workstations.

- Custom WIP Carts: Tailored to specific workflows, designed for specialized parts or tools.

- Multi-Level Carts: Ideal for handling different stages of assembly in a single trip.

The Role of WIP Racks in Manufacturing

The core function of a WIP rack is to improve the flow of materials between different manufacturing stages. By having organized mobile storage, workers spend less time searching for parts and more time on productive tasks. Additionally, WIP racks help reduce downtime caused by disorganized workspaces or delays in material handling. As a result, the use of WIP racks can lead to significant reductions in wasted time and resources.

How WIP Carts Maximize Productivity

- Reducing Transport Times: Organized materials on mobile platforms minimize transport times.

- Minimizing Errors and Damage: Parts are easily accessible and less likely to be damaged.

- Improving Workstation Organization: Materials stay organized and accessible.

Customization: Tailoring WIP Carts to Your Needs

One of the most significant advantages of WIP carts is their customizability. Many manufacturers require specialized solutions due to the nature of their products or production processes. Custom WIP carts can be designed with specific compartments, shelves, or tool holders, ensuring the cart perfectly matches the workflow. For example, an electronics manufacturer may need custom shelving to hold fragile circuit boards, while an automotive plant may require heavy-duty carts with unique holders for significant components.

WIP Racks vs. Traditional Storage Solutions

Traditional static storage solutions, such as shelves or pallets, often need more mobility and flexibility than WIP racks provide. With static storage, workers must constantly move back and forth between workstations and storage areas, wasting valuable time. On the other hand, WIP racks allow materials to move with the workflow, creating a more dynamic and efficient environment.

Industries That Benefit Most from WIP Carts

While WIP carts can benefit nearly any manufacturing operation, specific industries see particularly significant gains:

- Automotive Manufacturing: Handles bulky and heavy parts.

- Electronics Assembly: Safely transports delicate components.

- Food Processing: Maintains hygiene and organization.

- General Manufacturing: Enhances flexibility and mobility.

How to Choose the Right WIP Cart for Your Facility

When selecting a WIP cart for your facility, consider the following factors:

- Workflow and Space: Ensure the cart fits into your production layout.

- Load Capacity: Choose carts that handle the weight and size of materials.

- Ergonomics: Select carts designed to reduce worker strain.

Cost-Effectiveness of Work-in-Process Carts

While the initial investment in WIP carts might seem significant, the long-term savings they offer through improved efficiency, reduced downtime, and fewer damaged products outweigh the costs. Additionally, high-quality work-in-progress carts are incredibly durable and require minimal maintenance, making them a cost-effective solution.

Implementing WIP Carts into Your Workflow

Integrating WIP carts into your facility and production line can be done in a few simple steps:

- Assess Your Current Workflow: Identify areas where mobility and organization are lacking.

- Select the Right Cart: Choose a WIP cart that fits your needs.

- Train Your Team: Ensure workers know how to use and maintain the carts properly for maximum efficiency.

Work-in-Progress Carts and Lean Manufacturing

Work-in-process carts are a perfect fit for companies following lean manufacturing principles, which focus on reducing waste and maximizing value. By streamlining the flow of materials and reducing the need for excess storage, WIP carts help manufacturers eliminate unnecessary steps in the production process.

Maintenance and Longevity of WIP Carts

To ensure your WIP carts last, follow these maintenance best practices:

- Inspect carts regularly for damage or wear.

- Clean carts to remove debris.

- Lubricate wheels and moving parts.

Conclusion

The benefits of Work-in-Progress carts are clear. From improving workflow to reducing downtime, minimizing errors, and boosting overall productivity, WIP carts are an indispensable tool in modern manufacturing. Whether you choose a standard model or invest in a custom cart tailored to your specific needs, integrating WIP carts into your operation is a surefire way to streamline processes and stay competitive in today’s fast-paced manufacturing world.

FAQs

What is the difference between a WIP cart and a regular cart?

WIP carts are explicitly designed to transport materials between production stages. They often feature organizational elements that standard carts lack.

Can WIP racks be used in small manufacturing operations?

WIP racks are versatile and can be adapted for small and large operations.

Do I need a custom WIP rack?

If your production involves handling specialized parts or tools, a custom WIP rack can be tailored to meet those needs.

What materials are typically used to make WIP racks?

Depending on their intended use, WIP racks are commonly made from steel, aluminum, or heavy-duty plastics.

Are WIP carts compatible with automation systems?

Many WIP carts can be integrated into automated workflows, enhancing efficiency and reducing manual labor.