Plymouth Industries is proud to announce a new materials partnership with Jifram Extrusions and Custom Built Pallets, expanding functionality and performance across our line of MaxStax Portable Stack Racks, returnable shipping racks, work-in-progress (WIP) carts, and heavy-duty steel pallets.

This collaboration brings together Plymoth’s expertise in custom steel fabrication with Jifram’s innovation in Jifram Plastic Extrusions, creating high-strength, non-slip plastic deck surfaces that improve load stability, protect products, and enhance operator safety in demanding material-handling environments.

Enhanced Durability and Safety with Plastic Extrusions

The addition of plastic extrusion decking provides a lightweight, corrosion-resistant, and non-conductive surface option for MaxStax and other Plymouth rack systems. This upgrade enhances durability and reduces wear compared to traditional wood or steel decking, while maintaining a secure, slip-resistant base ideal for sensitive or irregular-shaped components.

For facilities requiring reliable solutions for storing and staging high-value products, such as electrical assemblies, tooling, or packaged goods, these portable warehouse stack racks deliver both versatility and protection. Customers can now request an instant plastic extrusion quote directly through Jifram to integrate extrusion-based features into new or existing Plymouth material-handling systems.

Optimized Storage and Handling Performance

Combining Jifram’s precision-engineered plastic surfaces with Plymouth’s proven MaxStax Portable Stack Racks results in safer stacking, smoother handling, and easier cleaning. The modular, returnable rack design supports space optimization in warehouses and production environments while reducing the need for disposable packaging or wood pallets.

Plymouth’s work-in-progress (WIP) carts and heavy-duty steel pallets can also be configured with these non-slip Jifram Extrusions, delivering consistent performance across a facility’s entire material-handling workflow, from fabrication to shipping.

Sustainable Alternatives with Custom-Built Pallets

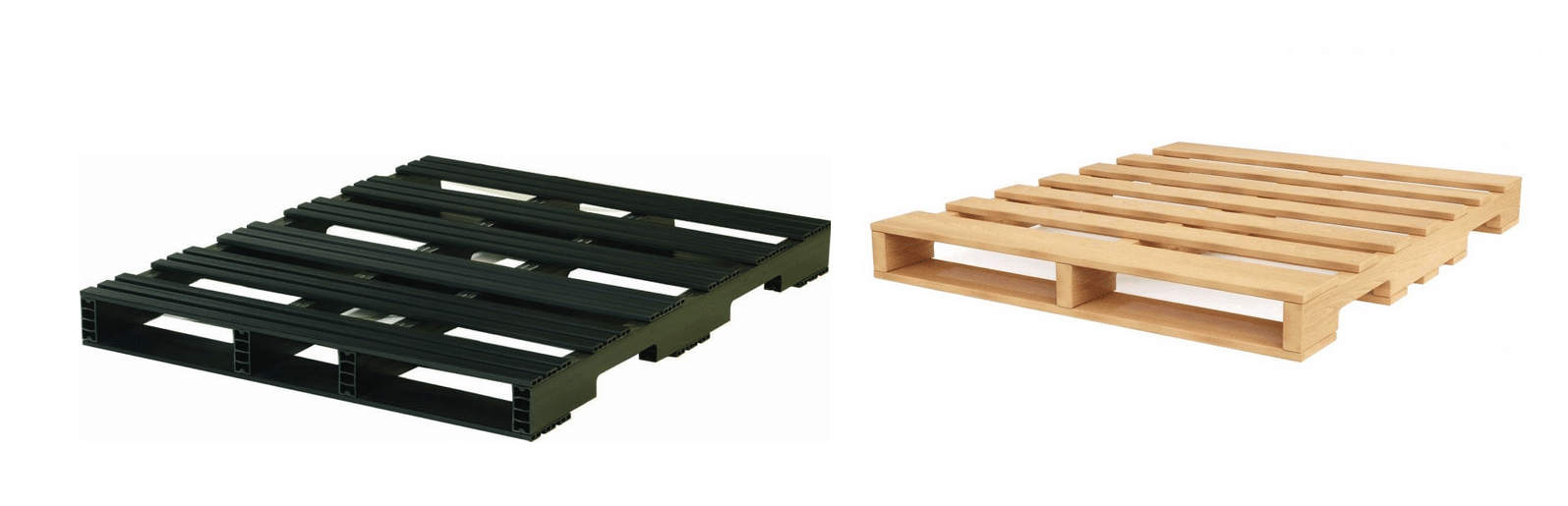

In addition to rack decking, Plymoth’s partnership with Custom Built Pallets expands access to reusable solutions, including custom-built plastic pallets, storage pads, and plastic skids. These products complement Plymouth’s steel-handling systems, offering hybrid options for companies focused on reducing waste and increasing the utilization of returnable assets.

By pairing durable metal structures with precision-formed plastic pallets, customers benefit from a unified storage and shipping ecosystem that’s easy to clean, long-lasting, and fully recyclable at the end of life.

Driving Efficiency Through Collaboration

The integration of Jifram Plastic Extrusions and Custom Built Pallets into Plymouth Industries’ engineered solutions marks an important step toward more adaptable, efficient, and sustainable material-handling systems. These partnerships bring together the strengths of three U.S. manufacturers committed to innovation, quality, and long-term value.

Ready to Upgrade Your Material Handling System?

Contact Plymouth Industries to discuss integrating non-slip Jifram Plastic Extrusions or custom-built pallets into your MaxStax Portable Stack Racks or other custom designs. Together, we’ll engineer a solution that maximizes safety, efficiency, and sustainability across your operation.