In the fast-paced world of warehousing and logistics, efficiency isn’t just a luxury—it’s a necessity. From fluctuating inventory to seasonal surges, warehouse managers face constant challenges in optimizing space, organizing goods, and ensuring fast, safe access. That’s where portable stack racks come into play—an often-overlooked hero of innovative storage solutions.

If you’re searching for ways to make your warehouse more agile, flexible, and space-efficient, it’s time to dive into the world of stack racks, also known as stacking racks, stacked racks, and stackable racks.

Why Every Warehouse Needs Stackable Racks

Warehouses often have too much inventory one week and too little the next. Adapting to this ebb and flow with traditional rack systems is nearly impossible without costly renovations. That’s where stackable racks shine.

These systems offer the following advantages:

- Flexibility

Move and rearrange your racks based on current inventory needs. - Space Optimization

Stack vertically to maximize cubic space. - Improved Workflow

Easier access to products speeds up picking and packing processes. - Temporary Storage

Perfect for overflow areas or staging zones.

In other words, stackable racks allow you to build your storage strategy around your inventory, not the other way around.

Portable Stack Racks vs. Traditional Pallet Racks

Let’s discuss comparisons. Traditional pallet racks are staples in most warehouses, but have limitations. They’re bolted down, they take up fixed space, and any reconfiguration often requires professionals (and downtime you can’t afford).

In contrast, portable stacking racks require no tools, installation, or permanent commitment. They can supplement your existing rack systems or replace them entirely if flexibility is a higher priority than fixed capacity.

Some key distinctions:

| Feature | Pallet Racks | Portable Stack Racks |

|---|---|---|

| Flexibility | Low | High |

| Installation | Permanent | Tool-free |

| Mobility | None | Easy to move |

| Space Efficiency | Good (static) | Excellent (dynamic) |

| Cost of Reconfiguration | High | Low to none |

How Portable Stacking Racks Improve Warehouse Safety

A cluttered warehouse is a dangerous warehouse. Stacked goods can fall, aisles can become blocked, and workers can get injured. Rack stacking with portable systems introduces order into chaos.

Stacking pallet racks keeps items off the floor, clearly categorized, and easily accessible. Better organization leads to fewer accidents and less product damage.

Additionally, stackable racks promote safer pallet stacking by providing a secure structure to prevent tipping or collapsing—a common hazard in high-volume environments.

Racking and Stacking for Seasonal Storage Needs

Have you ever needed to double your storage space for just a few months out of the year? Seasonal inventory surges are one of the biggest reasons to invest in portable stack racks.

Let’s say you’re a retailer prepping for the holiday rush. Your usual setup can’t handle the volume, but building out permanent storage isn’t practical. In this case, rack stacking offers the perfect short-term solution. Stack what and where you need it, and break it down when the season ends. It’s that simple.

Rack Systems That Scale With You

Business growth is great until your infrastructure starts lagging. With rack stack setups, your warehouse can scale as fast as your business.

You can start with a few racks for overflow areas and add more as needed. This “plug-and-play” model ensures your racks and stacks can grow with demand, without the upfront investment or downtime required by traditional racking.

Even better? They integrate seamlessly with forklifts and pallet jacks, so there’s no need for new equipment or retraining.

Sustainability Meets Stackability

Today’s warehouses aren’t just about profit—they’re about sustainability too. Stackable racks contribute to greener operations in a few key ways:

- Reduced Material Waste

No need for wood pallets or temporary shelving. - Efficient Space Use

Less square footage required, lowering HVAC and lighting costs. - Reusability

Built to last, with minimal maintenance.

Using portable stacking racks is a small change that adds to a significant environmental impact over time.

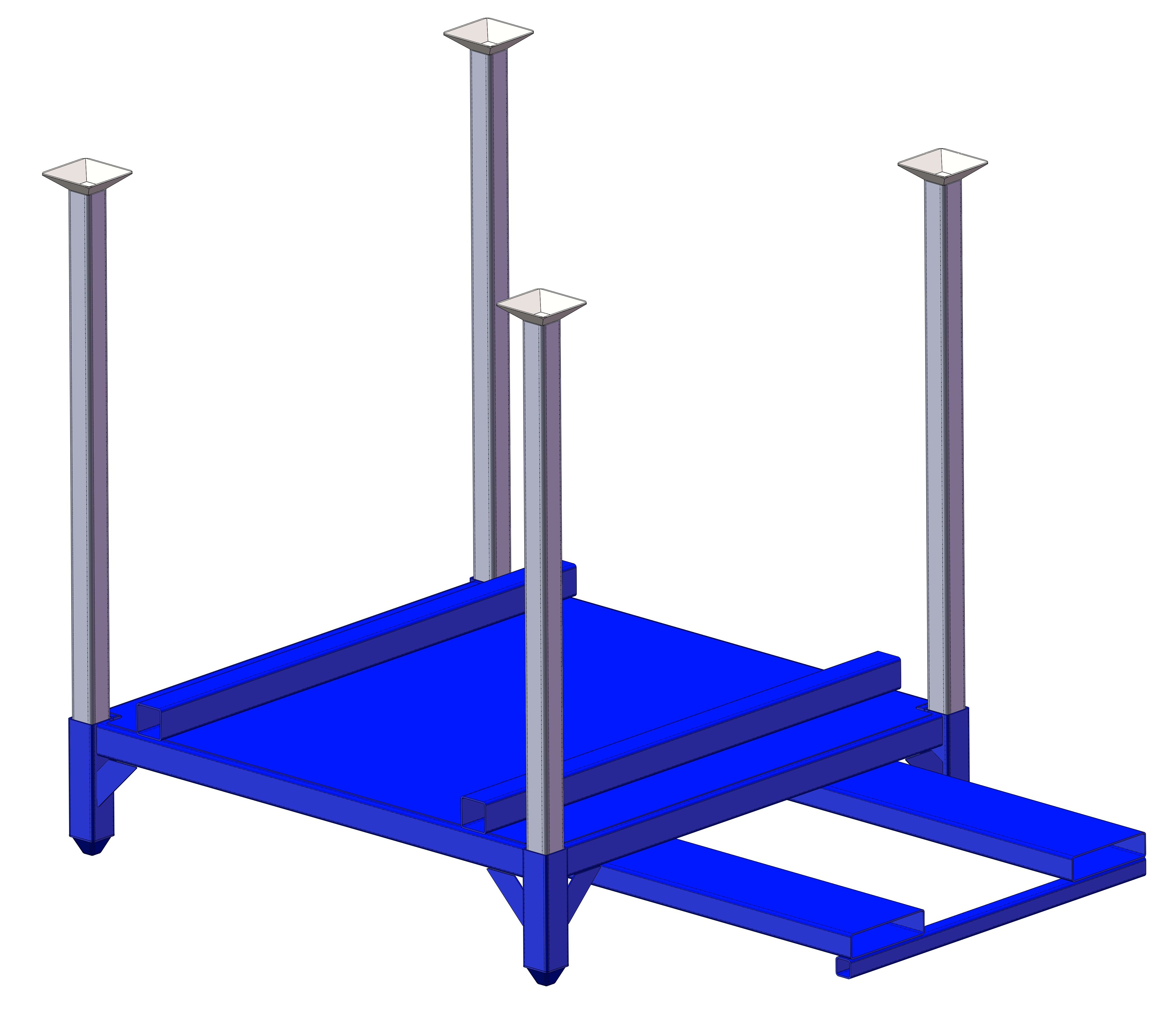

Custom Configurations for Unique Needs

Not all inventory is created equal. Some items are oddly shaped, heavy, or fragile. Thankfully, stacking racks come in various sizes, materials, and weight capacities.

Whether you’re storing tires, textiles, or totes, there’s a stack rack for the job. For ultra-secure handling, you can even find options with mesh sides, solid decks, or fork stirrups.

That kind of customization isn’t just a nice perk—it’s a necessity for specialized industries.

Portable Doesn’t Mean Weak

Don’t let the word “portable” fool you—these racks are built to handle serious weight. Depending on the configuration, heavy-duty stacking pallet racks can support thousands of pounds per unit.

They’re tough enough for steel coils, yet nimble enough for delicate inventory like glassware or electronics. This combination of strength and portability makes them ideal for nearly any warehouse environment.

Rethinking Warehouse Design with Stackable Racks

Modern warehouse design is all about agility. Fixed systems are becoming obsolete as businesses demand more responsive solutions.

Stacks and racks offer a modular approach to storage, letting you reshape your floor plan overnight. Want to turn unused dock space into a mini storage zone? Just move a few portable stacking racks into place.

These racks turn your warehouse into a Lego set—limited only by your creativity.

The Future is Flexible: Embrace Stack Rack Systems

Looking ahead, adaptability will continue to dominate warehousing strategy. Businesses that scale up, down, or sideways immediately will win in the long run.

That’s why investing in a stacking rack system now is smart—it’s also future-proof. As new technologies like automation and robotics integrate into warehouse operations, portable racks provide the perfect flexible framework to support that evolution.

Final Thoughts

In a world where every square foot counts, portable stack racks offer a smarter, safer, and more sustainable way to manage warehouse storage. Stacking racks can revolutionize your approach, whether dealing with seasonal surges, special inventory, or just trying to make the most of your space.

Forget about static storage. Think modular. Think flexible. Think stackable.

For warehouses that want to thrive—not just survive—stack racks aren’t just an option. They’re a necessity.

FAQs

- Are stack racks safe for heavy loads?

Yes, most stack racks are designed to handle thousands of pounds per rack. Always check manufacturer specs for exact load capacities. - Can I use stack racks outdoors?

Absolutely. Many models are made with weather-resistant coatings, making them suitable for outdoor use. - How do stack racks compare cost-wise to pallet racks?

While the initial cost per unit may be slightly higher, stack racks save money over time due to their portability and lack of installation costs. - Do stack racks require tools for assembly?

Nope! Most stack racks are tool-free and take just minutes to set up or break down. - Can I customize stack racks for specific inventory?

Many manufacturers offer custom options, from size and weight capacity to special decking and sides.