Manufacturers across the Midwest and beyond are under constant pressure to deliver high-quality parts faster and at lower cost, without sacrificing accuracy. Traditional fabrication methods often require multiple setups, secondary machining, and additional labor, which drive up prices and extend lead times. Tube laser cutting services solve these challenges by combining speed, precision, and efficiency into a single, streamlined process.

At Plymouth Industries, tube laser cutting is designed to help OEMs, fabricators, and procurement teams reduce total manufacturing cost while receiving parts that meet exact specifications. By cutting tubes and angles in one automated operation, this capability supports faster turnaround, competitive pricing, and consistent results from prototype through production.

Why Tube Laser Cutting Is a Smarter Fabrication Choice

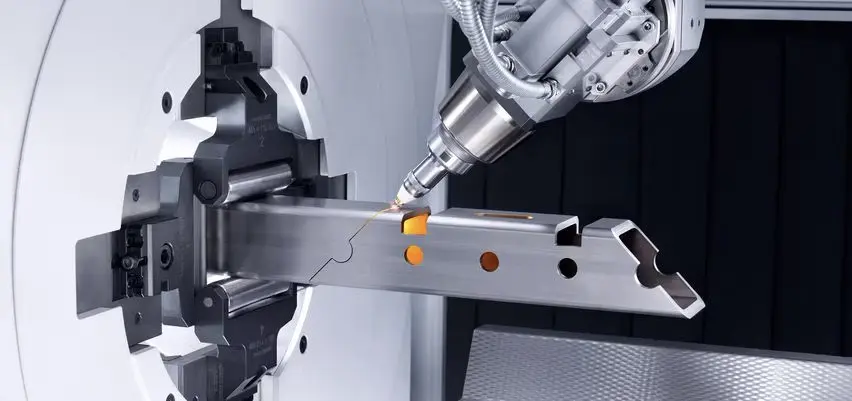

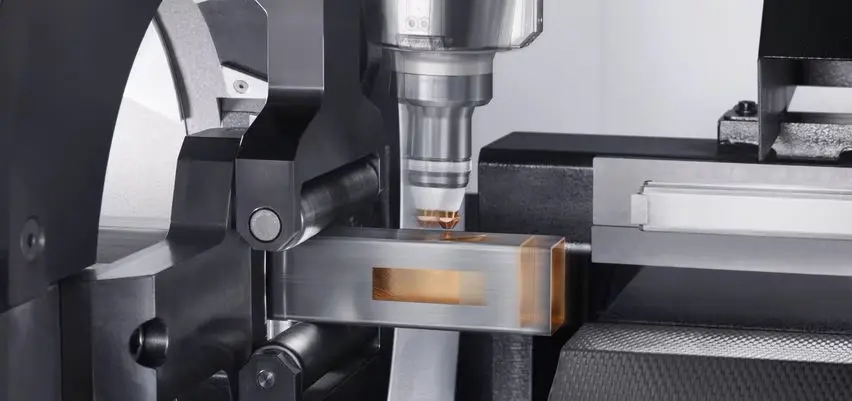

Tube laser cutting uses CNC-controlled lasers to cut and profile round tubing, square tubing, rectangular tubing, and structural angles with high precision. Unlike saw cutting or manual machining, laser processing can produce complex geometries in a single setup.

This approach replaces multiple fabrication steps, such as cutting, drilling, punching, and notching, with one controlled operation. The result is fewer touchpoints, less handling, and parts that are ready for assembly as soon as they leave the machine.

Lower Prices Through Fewer Operations

Cost control starts with process efficiency. Tube laser cutting services reduce manufacturing costs by eliminating labor-intensive secondary operations and minimizing scrap.

Key cost-saving advantages include:

- No tooling requirements, reducing upfront expense

- Lower labor costs by combining cutting and feature creation

- Reduced rework due to consistent, repeatable accuracy

- Efficient material usage through optimized CNC programming

Because the laser handles holes, slots, miters, and end cuts in one pass, there is no need for separate drilling or punching stations. This consolidation directly translates into lower per-part pricing, especially for repeat and production orders.

Fast Turnaround That Keeps Production Moving

Long lead times can disrupt schedules and increase carrying costs. Tube laser cutting dramatically shortens production timelines by reducing the number of fabrication steps required.

With fewer handoffs and setups, parts move through the shop faster. This speed is especially valuable for:

- Short-run and mid-volume production

- Engineering revisions or late-stage design changes

- Just-in-time manufacturing programs

Tube laser cutting services offer predictable turnaround times without compromising accuracy, enabling downstream processes such as welding, bending, or assembly to begin immediately.

Eliminate Secondary Operations Entirely

Secondary operations add risk, cost, and time. Each additional process introduces variability and the potential for error. Tube laser cutting services are engineered to eliminate these steps wherever possible.

Features commonly completed during laser cutting include:

- Precision holes and slots

- Coping and notching

- Mitered and angled end cuts

- Tabs and locating features

By integrating these details directly into the laser program, parts arrive dimensionally correct and ready for assembly. This reduces setup time during welding and ensures a consistent fit across assemblies.

Meeting Exact Part Specifications, Every Time

Precision is not optional for structural assemblies, material handling equipment, and engineered components. Tube laser cutting delivers the accuracy required to meet tight tolerances and exact part specifications.

CNC laser control ensures:

- Consistent hole location and geometry

- Clean edges with minimal finishing required

- Repeatable results across long production runs

- Reduced heat distortion compared to mechanical cutting

This level of control is essential for manufacturers that require dependable, assembly-ready components without added inspection or rework.

Capable of Cutting Tubes and Angles

One of the biggest advantages of tube laser cutting is versatility. The process supports a wide range of profiles and materials, allowing multiple part types to be produced using the same technology.

Capabilities include:

- Round tubing

- Square and rectangular tubing

- Structural angles

- Custom tubular profiles

By cutting tubes and angles in-house, manufacturers can simplify their supply chain and rely on one process for multiple component types.

Ideal for Prototypes and Production Runs

Tube laser cutting services scale efficiently from single prototypes to full production volumes. Engineers can validate designs quickly without investing in hard tooling, while production teams benefit from repeatable, automated output.

Because changes are made digitally within the CNC program, revisions can be implemented rapidly, supporting agile manufacturing and faster time-to-market.

Supporting Lean Manufacturing Goals

Lean manufacturing depends on reducing waste, minimizing work-in-process inventory, and shortening lead times. Tube laser cutting directly supports these goals by consolidating operations and improving flow.

Benefits for operations and procurement teams include:

- Fewer vendors and simplified sourcing

- Improved scheduling and planning

- Reduced total cost of ownership

- More reliable delivery timelines

By delivering parts that are ready for downstream processes, tube laser cutting helps manufacturers operate more efficiently and competitively.

Why Choose Plymouth Industries for Tube Laser Cutting Services

Plymouth Industries approaches tube laser cutting with a focus on practical manufacturing outcomes: competitive pricing, fast turnaround, and parts that meet specifications the first time. Each project is evaluated to ensure the most efficient cutting strategy, minimizing cost while maintaining accuracy.

From quoting through delivery, the emphasis remains on clear communication, consistent quality, and dependable performance, whether the job involves simple tube cuts or complex angle profiles.

Conclusion: Get Precision Tube Laser Cutting Without the Delays

Tube laser cutting services offer a proven way to reduce fabrication cost, eliminate secondary operations, and accelerate production timelines, while meeting exact part specifications. By cutting tubes and angles in a single, precise operation, manufacturers gain speed, accuracy, and cost control.

If you’re ready to reduce part costs and shorten lead times, contact Plymouth Industries today to discuss your tube laser-cutting needs and request a fast, competitive quote.